Heat is a very common problem in industrial plants. Insufficient cooling intervenes with the day-to-day operations of the plant, which causes the main problem of poor performance of the company. The rising temperature can make the environment within the premises uncomfortable, rendering it unsuitable for working conditions. In case employees are exposed to a prolonged period of excessive heat, it gives way to a phenomenon called heat stress that sharply affects the productivity of the workers. Therefore, achieving optimal industrial ventilation is imperative for industrial plants to ensure the highest performance from the employees.

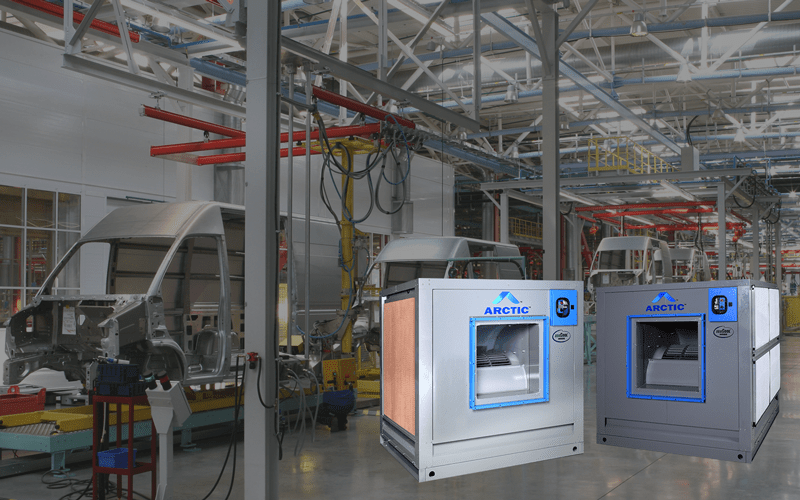

But considering that industrial spaces are inherently complex structures loaded with heavy machinery, cooling the premises becomes tricky. Additionally, the critical processes being carried out emanate a lot of heat that amplifies the heat issue of the space. This mandates the installation of a highly effective cooling solution to ventilate the industrial plants substantially. Controlling the temperature is essential to retain the integrity and efficiency of the industrial workspace.

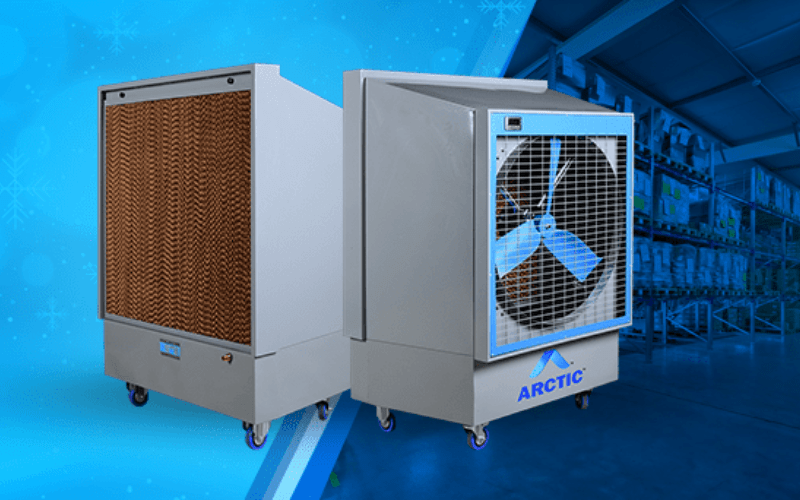

Along with the complexity of the place, a lot of energy is wasted in cooling down the extra space. Here, Industrial Evaporative Cooling is the most viable solution suitable for cooling such a large space. It is best suited to provide cooling solutions in the most economical way. It requires minimal capital costs for installations, and the average price for system setup is one-fourth the cost of setting up an air conditioning system.

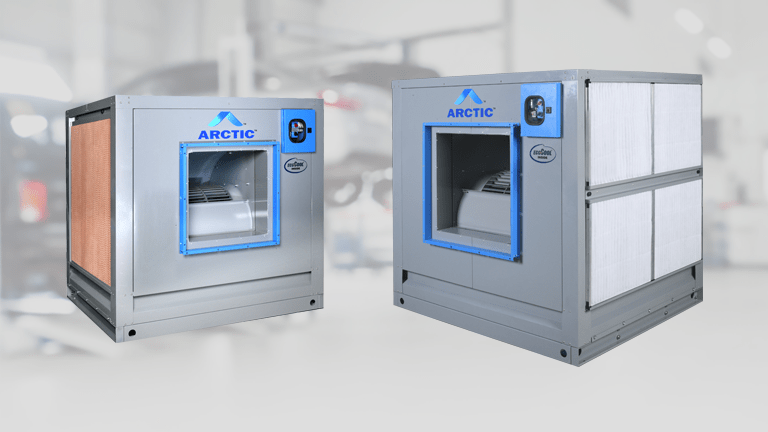

The mechanisms involved in Industrial Evaporative Cooling make use of natural resources, hence, the entire process is environmental-friendly. It extracts 100 percent natural fresh air from the surroundings to cool down the large industrial space. In the process, it also ensures a continuous supply of fresh oxygen to the room which removes all the fumes, odor, carbon dioxide, and other airborne impurities, and the built-in dust from the enclosed space. This continuous influx and circulation of fresh air reduce the sultriness within the premises. At the same time, it eliminates the stagnant indoor air, which is a major reason for the growth of viruses and bacteria. It is quite evident that evaporative cooling not just cools down the industrial plant, but also plays an imperative role in improving indoor air quality. It majorly contributes to reducing the carbon footprint.

Making use of natural resources, evaporative cooling automatically reduces the temperature by 10 °C to 12°C by simply filtering hot, dry air through the water-saturated cooling pads. Here, water evaporation initiates the formation of cool vapor to achieve the cooling effect. Along with this, the innovative cooling solution is well-equipped with high adsorbent materials responsible for amplifying saturation efficiency. All the factors cumulatively reduce the running cost of the machines by adding to the productivity of the machines. The energy consumption is substantially reduced where it utilizes 80 percent less electricity in comparison to other air conditioning alternatives available in the market. Installing brands like ARCTIC can efficiently help in meeting the air quality requirements, where it is adept at achieving cooling solutions in a comfortable and hassle-free way.

There are instances where the machines are vulnerable to getting damaged due to overheating of parts. Evaporative cooling with the help of its cooling solutions maintains the temperature at optimal levels that ensures the smooth functioning of the machines. Keeping the temperature cool, provides comfortable working conditions. As a result, the employees are better able to concentrate and deliver error-free work. This invariably boosts the productivity of the plant and adds to the profit stability of the company.