The article elaborates on how cooling solutions is vital for the smooth functioning of warehouses

Quality air solution to cool down warehouses is of utmost importance given to the inherently large space it poses. These areas have high ceilings; where all kinds of goods from lightweight cartons to heavy-load goods are stored. It forms an essential part of the logistics where goods are stockpiled to be moved from one place to another.

The warehouses are majorly managed by an on-ground workforce who use a mix of manual as well as heavy-weight machinery for the smooth movement of the goods. Given to the nature of work being carried inside tremendous amount of heat is invariably generated within the vicinity of the warehouse. Unfortunately, this gives rise to high temperatures making the working conditions unsuitable for people within the warehouse. Exposure to excessive heat can lead to a condition of heat stress which can acutely intervene with the working efficiency of the individuals and negatively affect their productivity. Therefore, temperature control is one of the most important and efficient factors required for the maintenance of the warehouse.

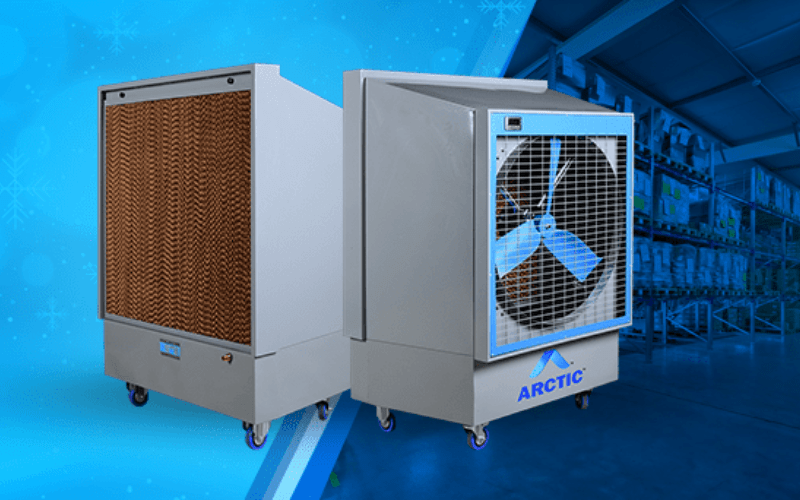

Considering the large area, Industrial Evaporative Cooling is the most economical cooling solution for warehouses. Cooling down a large warehouse at times becomes very tricky as going for conventional methods consumes a lot of energy. Compounding the problem, a lot of energy is wasted because of the extra space. In such instances, evaporative colling requires minimal capital cost for installation and the average cost to set up the system is one-fourth as compared to the air conditioning option.

Additionally, it is an energy-efficient mechanism making use of natural resources that further reduces the running costs of the machines. The best part of installing innovative cooling solutions are that it is being backed up with high saturation efficiency and highly adsorbent materials that amplify the efficiency of the system. This results in minimized consumption of energy accounting for 80 percent less electricity usage as compared to other alternatives.

As stated above as evaporative cooling utilizes natural resources it is highly environmentally-friendly in its approach. It works by taking 100 per cent natural fresh air from the surroundings for cooling down the large warehouse and at the same time also ensures that there is a continuous supply of oxygen within the premises. The mechanism is well adept at the influx and circulation of fresh air in the otherwise packed and sultry warehouse. This plays an instrumental role in effectively reducing the temperature by 10° C to 12° C by simply directing hot, dry air through the water-saturated cooling pads for filtration. As a result, the water evaporates which induces the formation of cooling vapor. This in addition to cooling down the warehouse also eliminates the stagnant indoor air which if left unattended can encourage the growth of viruses and bacteria. In the process, it gets rid of the fumes, odor, carbon dioxide & other airborne impurities, and built-in dust from the enclosed air and consequently improves the indoor air quality at the same time. Cumulatively, it is a given that industrial evaporative cooling is helpful in reducing the carbon footprint.

In addition to the above-stated benefits, the cooling solution is vital to ensure the smooth functioning of the machines which could potentially be damaged due to the overheating of the parts. On the other hand, maintaining a cool temperature helps the employees to deliver error-free work that boosts their morale and productivity which adds to the profitability of the company.