+91 7669100294

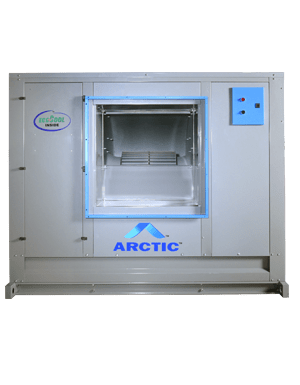

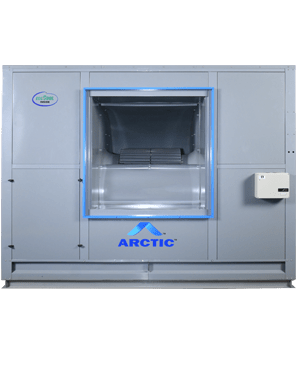

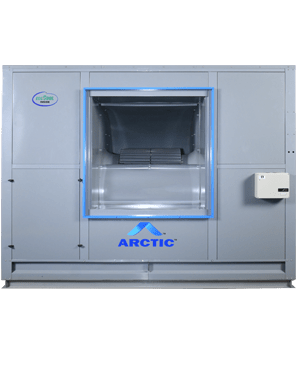

Ducted Evaporative Cooler

World's Best Performing Evaporative Air Washer

Arctic Ducted Evaporative Coolers are the best in the world. These robust strong body coolers are ideal for central cooling using ducts across applications. The range uses a centrifugal fan, specially designed cooling pads and unique design features coming from decades of engineering knowledge. The range offers excellent cooling and air delivery.

Arctic Ducted Evaporative Cooler can lower the fresh air dry bulb temperature by 7-12°C, e.g.- the air-off temperature from the evaporative cooler for an outside temperature of 40-43°C can be as low as 28-30°C.

Reduction of temperature & fresh air in the workplace create a healthy environment and benefits like improved staff morale, increased productivity & accuracy and less absenteeism.

Features

World's Best Performing Ducted Evaporative Cooler with highest cooling efficiency.

Built with high static pressure for comprehensive area coverage through long ducts and numerous grill for better air management..

AMCA Certified DIDW Blowers.

Most robust, rustproof metal body with heavy duty pre-coated GSS.

Proudly made in India at our world-class manufacturing plant.

Branded Spares used for its manufacturing for an easy repair or replacement.

Special Pre-plasticsized coated galvanised steel

Centrifugal DIDW

Benefits

An environment-friendly air cooling solution

Specifically designed for the cooling of large industrial and commercial spaces.

Trusted brand & innovative Technology.

Wide Range of models available to cool large areas economically Works well in harsh outdoor conditions, installation or usage.

Easy to install at the site No assembly required, no trial & error for motors

Long, trouble-free life compared to cheap imported plastic body coolers.

Duct designing expertise provided by the company.

Ideal for

Maintaining Human Comfort, Heat Removal, Process needs, Increasing work efficiency & accuracy, Open spaces & Large areas.

Offices

Schools

Multiplexes

Commercial Complexes

Restaurant

Company Canteens & Kitchens

Shopping Malls

Banquets

Marriage Halls

Gymnasiums

Poultry

Green House & Nursery

Textile Mills

Plastic Printing & Packaging Industry

General Manufacturing facilities

Tea Factories

Ideal for

Maintaining Human Comfort, Heat Removal, Process needs, Increasing work efficiency & accuracy, Open spaces & Large areas.

Commercial Facilities

- Offices, Schools, multiplexes & Commercial Complexes.

- Restaurant, Company canteens & Kitchens

- Shopping Malls, Banquets, Marriage Halls

- Gymnasiums

- Residential Buildings

- Paultry

- Green House & Nursery

Industrial Facilities

- Textile Mills

- Automotive Industry

- Plastic Printing & Packaging Industry

- General Manufacturing facilities

- Tea Factories

- Workshops & Warehouses

Range of Products

Largest range of ARCTIC standard ducted coolers - from 8000 CMH to 120000 CMH. They are Heavy-duty metal coolers with the highest efficiency & unique three side pad design & blowers for the most powerful air throw. with EcoCool Pads, Prefilters & inbuilt control panel - ARCTIC coolers are the world's best performing evaporative air coolers.

Arctic Discharge Cooler ADC – 20K

Arctic Discharge Cooler ADC – 20K |

Arctic Discharge Cooler ADC – 25K

Arctic Discharge Cooler ADC – 25K |

Arctic Discharge Cooler ADC – 35K

Arctic Discharge Cooler ADC – 35K |

Arctic Discharge Cooler ADC – 45K

Arctic Discharge Cooler ADC – 45K |

||

| Description | UOM | ADC – 20K | ADC – 25K | ADC – 35K | ADC – 45K |

| Minimum Evaporation Efficiency | % | 90 | 90 | 90 | 90 |

| Pad Surface Area | m2 | 1.56 | 2.17 | 3.74 | 6.06 |

| Pad Thickness | mm | 100 | 100 | 100 | 100 |

| Connection Load | kw | 0.79 | 1.55 | 3.88 | 5.87 |

| Power Supply | 230/1Ph/50Hz | 415/3Ph/50Hz | 415/3Ph/50Hz | 415/3Ph/50Hz | |

| Overall Dimensions (L x W x H) | mm | 1100x1100x850 | 1100x1100x1100 | 1250x1500x1400 | 1750x2150x1650 |

| Duct Connection Size | mm | 400 x 400 | 400 x 400 | 650 x 650 | 900 x 900 |

| Tank Capacity | Liter | 110 | 110 | 190 | 475 |

| Dry Weight* | Kgs | 165 | 200 | 295 | 565 |

| Design Guide- SI Units | |||||

| Air Flow at given ESP | m3/h | 8000 | 11000 | 26000 | 45000 |

| Static Pressure | mmWC | 19 | 22 | 22 | 22 |

| External Static Pressure | mmWC | 5 | 10 | 10 | 10 |

| Air Flow at below ESP | m3/h | 5100 | 6800 | 15300 | 25500 |

| Static Pressure | mmWC | 22.5 | 32 | 32 | 40 |

| External Static Pressure | mmWC | 10 | 20 | 20 | 30 |

Arctic Discharge Cooler ADC – 85K

Arctic Discharge Cooler ADC – 85K |

Arctic Discharge Cooler ADC – 100K

Arctic Discharge Cooler ADC – 100K |

Arctic Discharge Cooler ADC – 125K

Arctic Discharge Cooler ADC – 125K |

|||

| Description | UOM | ADC – 85K | ADC – 100K | ADC – 125K | |

| Minimum Evaporation Efficiency | % | 90 | 90 | 90 | |

| Pad Surface Area | m2 | 9.08 | 13.88 | 13.88 | |

| Pad Thickness | mm | 100 | 100 | 100 | |

| Connection Load | kw | 9.67 | 10.05 | 15.75 | |

| Power Supply | 230/1Ph/50Hz | 415/3Ph/50Hz | 415/3Ph/50Hz | ||

| Overall Dimensions (L x W x H) | mm | 2300x2400x1850 | 2300x3300x2400 | 2300x3300x2400 | |

| Duct Connection Size | mm | 1100×1100 | 1250×1250 | 1400×1400 | |

| Tank Capacity | Liter | 715 | 1000 | 1000 | |

| Dry Weight* | Kgs | 790 | 910 | 1010 | |

| Design Guide- SI Units | |||||

| Air Flow at given ESP | m3/h | 75000 | 90000 | 120000 | |

| Static Pressure | mmWC | 22 | 22 | 22 | |

| External Static Pressure | mmWC | 10 | 10 | 10 | |

| Air Flow at below ESP | m3/h | 42500 | 51000 | 68000 | |

| Static Pressure | mmWC | 40 | 40 | 40 | |

| External Static Pressure | mmWC | 30 | 30 | 30 | |

|

|

|

|

|

|

|

|

| Modal | ADC - 20K | ADC - 25K | ADC - 35K | ADC - 45K | ADC - 85K | ADC - 100K | ADC - 125K |

| Body Material | Special Pre-plasticsized coated galvanished steel | ||||||

| Minimum Evaporation Efficiency (%) | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Pad Surface Area (m2) | 1.56 | 2.17 | 3.74 | 6.06 | 9.08 | 13.88 | 13.88 |

| Pad Thickness (mm) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Connection Load (kw) | 0.79 | 1.55 | 3.88 | 5.87 | 9.67 | 10.05 | 15.75 |

| Power Supply | 230/1Ph/50Hz | 415/3Ph/50Hz | |||||

| Overall Dimensions (L x W x H) (mm) | 1150x1150x950 | 1150x1150x1150 | 1450x1550x1450 | 1750x2350x1750 | 2150x2400x2150 | 2150x2400x2150 | 2300x3300x2500 |

| Duct Connection Size (mm) | 400 x 400 | 400 x 400 | 650 x 650 | 900 x 900 | 1100 x 1100 | 1250 x 1250 | 1400 x 1400 |

| Fan Type | Centrifugal DIDW (Double inlet Double Width) | ||||||

| Tank Capacity (Liter) | 110 | 110 | 190 | 475 | 715 | 1000 | 1000 |

| Dry Weight* (Kgs) | 165 | 200 | 295 | 565 | 790 | 910 | 1010 |

| * Industrial long life construction (heavy duty) | |||||||

| Design Guide- SI Units | |||||

| Model | Air Flow at given ESP (m3/h) | External Static Pressure (mmWC) | Air Flow at below ESP | External Static Pressure (mmWC) | |

| ADC - 20K | 8000 | 5 | 5100 | 10 | |

| ADC - 25K | 11000 | 10 | 6800 | 20 | |

| ADC - 35K | 26000 | 10 | 15300 | 20 | |

| ADC - 45K | 45000 | 10 | 25500 | 30 | |

| ADC-L-85K | 75000 | 10 | 42500 | 30 | |

| ADC-L-100K | 90000 | 10 | 51000 | 30 | |

| ADC-L-125K | 120000 | 10 | 68000 | 30 | |

|

||

| Model | ADC - 20K | |

| Body Material | Special Pre-plasticsized coated galvanished steel | |

| Minimum Evaporation Efficiency (%) | 90 | |

| Pad Surface Area (m2) | 1.56 | |

| Pad Thickness (mm) | 100 | |

| Connection Load (kw) | 0.79 | |

| Power Supply | 230/1Ph/50Hz | |

| Overall Dimensions (L x W x H) (mm) | 1150x1150x950 | |

| Duct Connection Size (mm) | 400 x 400 | |

| Fan Type | Centrifugal DIDW (Double inlet Double Width) | |

| Tank Capacity (Liter) | 110 | |

| Dry Weight* (Kgs) | 165 | |

| * Industrial long life construction (heavy duty) | ||

| Design Guide- SI Units | |

| Model | ADC - 20K |

| Air Flow at given ESP (m3/h) | 8000 |

| External Static Pressure (mmWC) | 5 |

| Air Flow at below ESP | 5100 |

| External Static Pressure (mmWC) | 10 |

|

||

| Model | ADC - 25K | |

| Body Material | Special Pre-plasticsized coated galvanished steel | |

| Minimum Evaporation Efficiency (%) | 90 | |

| Pad Surface Area (m2) | 2.17 | |

| Pad Thickness (mm) | 100 | |

| Connection Load (kw) | 1.55 | |

| Power Supply | 415/3Ph/50Hz | |

| Overall Dimensions (L x W x H) (mm) | 1150x1150x1150 | |

| Duct Connection Size (mm) | 400 x 400 | |

| Fan Type | Centrifugal DIDW (Double inlet Double Width) | |

| Tank Capacity (Liter) | 110 | |

| Dry Weight* (Kgs) | 200 | |

| * Industrial long life construction (heavy duty) | ||

| Design Guide- SI Units | |

| Model | ADC - 25K |

| Air Flow at given ESP (m3/h) | 11000 |

| External Static Pressure (mmWC) | 10 |

| Air Flow at below ESP | 6800 |

| External Static Pressure (mmWC) | 20 |

|

||

| Model | ADC - 35K | |

| Body Material | Special Pre-plasticsized coated galvanished steel | |

| Minimum Evaporation Efficiency (%) | 90 | |

| Pad Surface Area (m2) | 3.74 | |

| Pad Thickness (mm) | 100 | |

| Connection Load (kw) | 3.88 | |

| Power Supply | 415/3Ph/50Hz | |

| Overall Dimensions (L x W x H) (mm) | 1450x1550x1450 | |

| Duct Connection Size (mm) | 650 x 650 | |

| Fan Type | Centrifugal DIDW (Double inlet Double Width) | |

| Tank Capacity (Liter) | 190 | |

| Dry Weight* (Kgs) | 295 | |

| * Industrial long life construction (heavy duty) | ||

| Design Guide- SI Units | |

| Model | ADC - 35K |

| Air Flow at given ESP (m3/h) | 26000 |

| External Static Pressure (mmWC) | 10 |

| Air Flow at below ESP | 15300 |

| External Static Pressure (mmWC) | 20 |

|

||

| Model | ADC - 45K | |

| Body Material | Special Pre-plasticsized coated galvanished steel | |

| Minimum Evaporation Efficiency (%) | 90 | |

| Pad Surface Area (m2) | 6.06 | |

| Pad Thickness (mm) | 100 | |

| Connection Load (kw) | 5.87 | |

| Power Supply | 415/3Ph/50Hz | |

| Overall Dimensions (L x W x H) (mm) | 1750x2350x1750 | |

| Duct Connection Size (mm) | 900 x 900 | |

| Fan Type | Centrifugal DIDW (Double inlet Double Width) | |

| Tank Capacity (Liter) | 475 | |

| Dry Weight* (Kgs) | 565 | |

| * Industrial long life construction (heavy duty) | ||

| Design Guide- SI Units | |

| Model | ADC - 45K |

| Air Flow at given ESP (m3/h) | 45000 |

| External Static Pressure (mmWC) | 10 |

| Air Flow at below ESP | 25500 |

| External Static Pressure (mmWC) | 30 |

|

||

| Model | ADC-L-85K | |

| Body Material | Special Pre-plasticsized coated galvanished steel | |

| Minimum Evaporation Efficiency (%) | 90 | |

| Pad Surface Area (m2) | 9.08 | |

| Pad Thickness (mm) | 100 | |

| Connection Load (kw) | 9.67 | |

| Power Supply | 415/3Ph/50Hz | |

| Overall Dimensions (L x W x H) (mm) | 2150x2400x2150 | |

| Duct Connection Size (mm) | 1100 x 1100 | |

| Fan Type | Centrifugal DIDW (Double inlet Double Width) | |

| Tank Capacity (Liter) | 715 | |

| Dry Weight* (Kgs) | 790 | |

| * Industrial long life construction (heavy duty) | ||

| Design Guide- SI Units | |

| Model | ADC-L-85K |

| Air Flow at given ESP (m3/h) | 75000 |

| External Static Pressure (mmWC) | 10 |

| Air Flow at below ESP | 42500 |

| External Static Pressure (mmWC) | 30 |

|

||

| Model | ADC-L-100K | |

| Body Material | Special Pre-plasticsized coated galvanished steel | |

| Minimum Evaporation Efficiency (%) | 90 | |

| Pad Surface Area (m2) | 13.88 | |

| Pad Thickness (mm) | 100 | |

| Connection Load (kw) | 11.75 | |

| Power Supply | 415/3Ph/50Hz | |

| Overall Dimensions (L x W x H) (mm) | 2150x2400x2150 | |

| Duct Connection Size (mm) | 1250 x 1250 | |

| Fan Type | Centrifugal DIDW (Double inlet Double Width) | |

| Tank Capacity (Liter) | 1000 | |

| Dry Weight* (Kgs) | 910 | |

| * Industrial long life construction (heavy duty) | ||

| Design Guide- SI Units | |

| Model | ADC-L-100K |

| Air Flow at given ESP (m3/h) | 90000 |

| External Static Pressure (mmWC) | 10 |

| Air Flow at below ESP | 51000 |

| External Static Pressure (mmWC) | 30 |

|

||

| Model | ADC-L-125K | |

| Body Material | Special Pre-plasticsized coated galvanished steel | |

| Minimum Evaporation Efficiency (%) | 90 | |

| Pad Surface Area (m2) | 13.88 | |

| Pad Thickness (mm) | 100 | |

| Connection Load (kw) | 15.75 | |

| Power Supply | 415/3Ph/50Hz | |

| Overall Dimensions (L x W x H) (mm) | 2300x3300x2500 | |

| Duct Connection Size (mm) | 1400 x 1400 | |

| Fan Type | Centrifugal DIDW (Double inlet Double Width) | |

| Tank Capacity (Liter) | 1000 | |

| Dry Weight* (Kgs) | 1010 | |

| * Industrial long life construction (heavy duty) | ||

| Design Guide- SI Units | |

| Model | ADC-L-125K |

| Air Flow at given ESP (m3/h) | 120000 |

| External Static Pressure (mmWC) | 10 |

| Air Flow at below ESP | 68000 |

| External Static Pressure (mmWC) | 30 |

Request for

a Call Back

Fill in all details & our experts will get in touch with you shortly.