Factories are inherently complex structures for carrying out the manufacturing of products. It is characterised by large space with heavy machinery for various critical processes entailing design specification, the assemblage of parts, processing of raw materials, and executing other crucial operations as well. As a result, a lot of heat is generated within the space. Given the complicated nature of activities taking place, which can negatively impact the quality of end-products and at the same time create an uncomfortable environment that meddles with the working efficiency of the employees.

As the heat problem can effectively reduce the comfort, productivity, and accuracy of the employees, it can in turn affect the profitability of the company. Hence, there is a need for quality air solutions to curtail the impact of high temperature within the premises of the factory. But given the large space, arranging for suitable air solutions is very tricky. The option of air conditioning is ruled out as it is very challenging to install a large number of systems and the installation, operational, and maintenance costs posed by the system can put a lot of pressure on the financial front of the company.

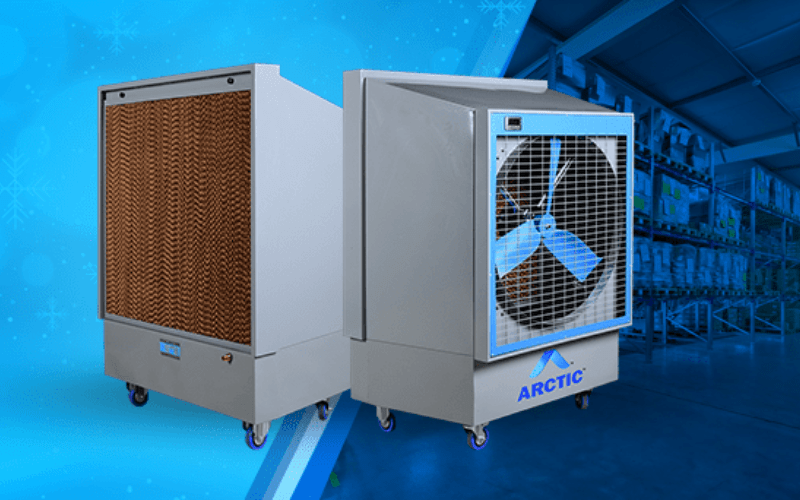

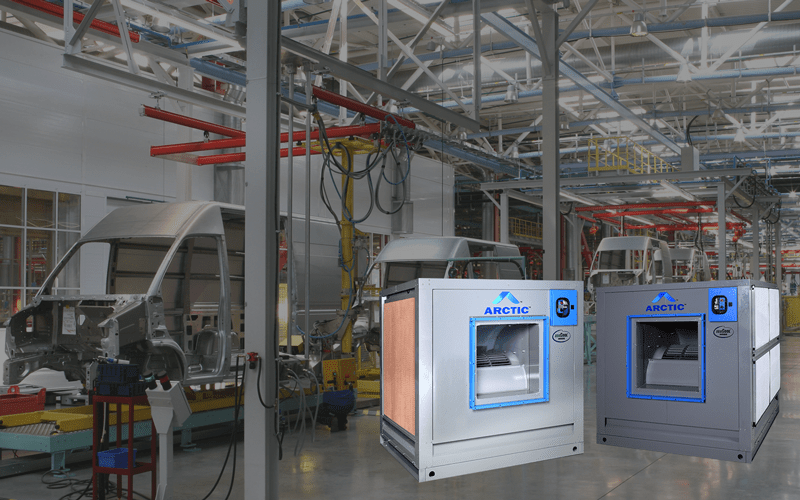

Here, industrial evaporative cooling emerges as a suitable solution for meeting the demanding requirement of factory setup. It is adept at providing cooling solutions for large spaces in the most economical way with the help of factory cooling systems. The technology is effective throughout warm and tropical weather conditions.

The approach is very simple where it makes use of 100 percent natural fresh air from ambient surroundings and at the same time makes sure to continuously supply oxygen and cool down the large factory space in the most environment-friendly way. It effectively brings down the temperature by 10-12 °C with the simple mechanism of drawing-in hot, dry air that is filtered and cooled through the water-saturated cooling pads. As a result, water evaporates by initiating the formation of cooling vapor. While ensuring a continuous supply of fresh air, the evaporative coolers not just cool down the large space but due to positive pressure also help in eliminating the stagnant air that inhibits the growth of viruses and bacteria. Therefore, its role goes beyond reducing the temperature within the factory premises and plays an instrumental part in improving the indoor air quality by removing fumes, odor, carbon dioxide, and other airborne impurities along with the inbuilt dust from the space. Consequently, the rate of illness occurring from bad air quality is curbed substantially.

It is the most energy-efficient solution, as it makes use of natural sources that invariably bring down the running cost of the system. Additionally, the coolers are self-supporting and backed up with highly adsorbent materials helping in high saturation efficiency that further contributes to the superior performance of the system. Given all the advantages, industrial evaporative cooling utilizes less fan power to achieve the same level of cooling that is provided by air conditioners. Also, it consumes 80 percent less electricity which drastically reduces the operational costs of the machines. Adding on to the already existing list of benefits, the installation costs also require small investments. Working with an established brand like ARCTIC for all your quality air requirements will provide you the comfort, trust, and a tension-free cooling solution. The decades of knowledge and expertise in duct designing, cooling pads, exhaust systems, etc. across diversified applications is what you get complimentary along with the product.

As a whole, this innovative cooling solution is adept at providing cool comfortable working conditions in the critical factory setup across a wide range of industries like automotive, food, engineering, textile, plastics, etc. This majorly contributes to enhancing the productivity of the employees who in the hot and stuffy conditions would have been unable to concentrate and deliver incompetent work due to the reduced accuracy in their performance. Consequently, there is a positive impact on the revenue generation of the company which makes evaporative coolers ideal and the most economical solution for factory cooling.